Full automatic one pull one mask machine

detail intruduction

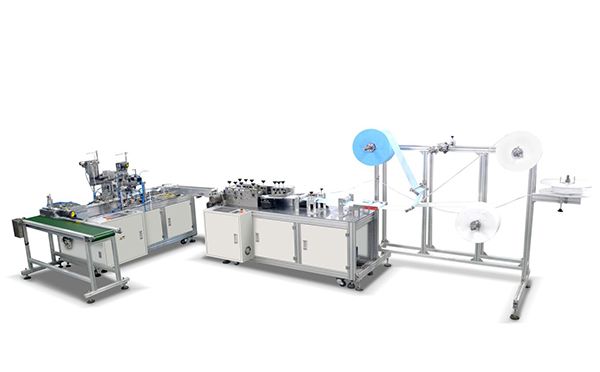

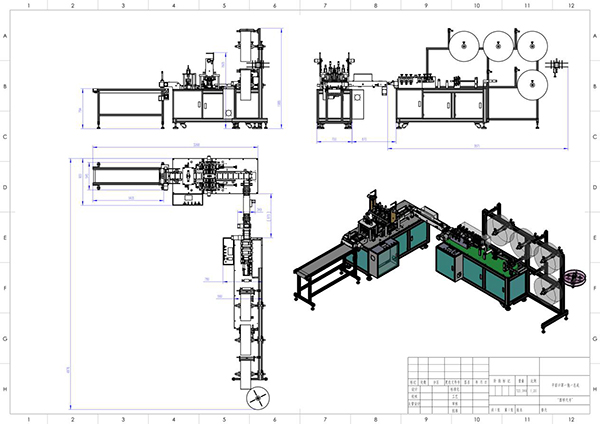

Full-automatic face mask making production line GC-19501

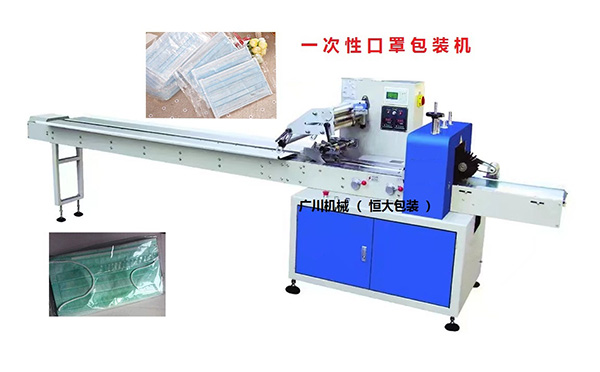

Sample photos:

(advantage) advantage1 The whole machine adopts aluminum alloy structure, which is more beautiful and sturdy2 High stability3 The full-automatic external ear belt spot welding machine can simultaneously make the mask sheet and the external ear welding spot welding part, which can save labor. Once the non-woven fabric raw materials are used up in the production process, the machine can automatically stop. Fully automatic outer ear spot welding machine produces masks sheet and outer ear welding spot welding part at the same time, which can save labor Once the non woven fabric material is used up in the production process, the machine will automatically stop

Production line structure: a host (mask forming machine) and a servo ear belt welding machine (external ear belt) are connected through a transmission line. It can realize the full-automatic production process of coil feeding, folding and pressing forming, slitting, ear belt feeding machine welding and blanking. A host (masks forming machine) plus two ear band welding machines (outer ear bands) are connected by a one-to-one transmission line It can achieve the full-automatic production process from coil feeding, folding and pressing, and sliding, ear band feeding machine welding, and unloading Technical parameter:

Machine model

GC-1950-1

Output

80-120 pieces / min

Voltage

220V/50hz

Machine dimension

5300*3300*1700mm ((length * width * height) 5300*3300*1700mm ((l*w*h)

Mask size

17.5*9.5cm

Power

11KW

Machine weight

1000Kg

Three tier raw material report:

Serial number

Melt blown cloth

Non woven fabric

Non woven fabric

Nose bridge strip

Ear belt

Pictures

Specification scale

(width):17.5cm gram weight:20g

(width):17.5cm gram weight:20g

(width):19.5cm gram weight:25g

Width: 3mm thickness: 1mm length: 95mm

Width: 2.5mm length: 20cm

Main machine configuration sheet:

The one driven one full-automatic plane mask production line adopts advanced design. It only needs to install the production raw materials on the feeding rack. After the modulation is completed, the machine can realize automatic production. Only one person is required to operate the packaging, which fully realizes the whole process automatic production. The equipment adopts ultrasonic welding method, with beautiful style, health and environmental protection.

The output is 80-120 pieces per minute, the length of the nose bar is adjustable, and the product size error is ± 1mm. Various specifications of mask pieces can be realized by changing some molds according to the demand. This machine can produce various non-woven mask, smooth cloth mask, gauze mask, activated carbon mask, double nose line mask, etc.

1. The one-to-one full automatic flat masks production line advances advanced design It only needs to place the raw materials on the feeding rack After the modulation is completed, the machine can automatically produce Only one person needed to operate the packaging, which fully realizes the entire automated production The equipment advocates ultra sonic welding method, with beautiful appearance, sanitation and environmental protection

The output is 80-120 per minutes, the length of the nose bridge strip is adjustable, and the product size error is fluctuating to 1 millimetre. According to the needs of replacing some molds, a variety of masks sheets can be achieved. This machine can produce non-woven masks, smooth cloth masks, gauze masks, activated carbon masks, double nose line masks, etc.

2. configuration list

Serial number

type

brand

Remarks

1

touch screen

Kunlun Tongtai

2

PLC

Siemens

3

Intermediate relay

OMRON

4

Circuit breaker

Schneider

5

contactor

Schneider

6

Two position rotary button

Schneider

7

Jog button

Schneider

8

Jog button

Schneider

9

Jog button

Schneider

10

Emergency stop button

Schneider

11

inverter

Schneider

12

Cooling fan

China

NO.

Name

Brand

Specification

1

touch screen

MCGS

2

PLC

SIEMENS

3

auxiliary relay

OMRON

4

Circuit breaker

Schneider

5

Contactor

Schneider

6

Two Button rotary switch

Schneider

7

Inching button

Schneider

8

Inching button

Schneider

9

Inching button

Schneider

10

Scram button

Schneider

11

Frequency transformer

Schneider

12

Radiator fan

China

Serial number item

Product name

Product picturepicture

Machine advantage description

1

Cutting rubber spoke & Cuttingrubber poke & Traction roller

We use steel to cover both sides of the rubber root, so the rubber will not break from the side after long-term use. Use silicone rubber instead of butyl wax. Silicone rubber material has good wear resistance and will not crack. Use steel covers the two sides of the rubber root to prevent breakdown after long time operation Use silicone rubber material instead of butadiene wax Silicon rubber has good wear resistance and will notcrack

2

PLC touch panel

Siemens PLC system. Siemens plckunluntongtai touch panel

3

Nose bridge feeding device

We use the nose bar direct feeding device, which can ensure that the nose bar can be inserted more straightly during the processing, so the finished mask will be flat and beautiful. Directly feed the nose bridge to device to ensure the nose bridge inserted more carefully, so the finished mask will be flat and look nice

4

Electric control box

We use Siemens PLC system

5

Motor

Gear motor

6

Fan

We installed the fan near the ultrasonic horn to reduce the temperature of the horn and prolong the service life of the ultrasonic. Install the fan near the ultrasonic horn to reduce the temperature of the horn and extend the ultrasonic life

7

Ultrasonic welding system

There is an ultrasonic system in the mask body machine. One ultrasonic system in the mask machine

Configuration sheet of servo ear band spot welding part: the servo type ear band welding machine uses ultrasonic welding to fuse the elastic band at both ends of the mask. Only one operator is required to place the mask body piece by piece in the mask panel, and the subsequent actions are automatically completed by the equipment until the finished product is completed. This machine adopts servo and step-by-step drive, with accurate transmission and adjustable speed. Ultrasonic welding method is adopted to fuse the elastic band to the inner side of both ends of the mask body, which is the last processing procedure of the inner ear mask production Only one operator needs to place the mask body piece by piece in the mask plate, and the equipment will automatically complete the following actions until the finished product This machine adopts serve step drive, drive accurate, speed adjustable

Technical parameter

Machine dimension

2100*1000*1600mm

Voltage

AC 220V,50-60HZ

Production speed

80-120 PCs/min

Power

2.7KW

Configuration list

Serial number

type

brand

Remarks

1

touch screen

Kunlun Tongtai

2

PLC

Siemens

3

PLC extension

Siemens

4

Intermediate relay

OMRON

5

Circuit breaker

Schneider

6

contactor

Schneider

7

Two position rotary button

Schneider

8

Jog button

Schneider

9

Jog button

Schneider

10

Jog button

Schneider

11

Emergency stop button

Schneider

12

Switching Mode Power Supply

Mingwei

13

Cooling fan + square dust cover (gray)

China

14

servo motor

Mitsubishi

15

Servo motor driver

Mitsubishi

16

cylinder

AirTAC

17

ultrasonic

China

18

solenoid valve

Taiwan gold ware

19

Proximity switch

OMRON

20

Photoelectric switch

OMRON

21

Single phase motor

Songgang

22

Air switch

Schneider

No.

Name

Brand

Specification

1

Touch Screen

MCGS

2

PLC

Siemens

3

PLC Expansion

Siemens

4

Auxiliary Relay

OMRON

5

Circuit Breaker

Schneider

6

Contactor

Schneider

7

Two Button rotary switch

Schneider

8

Inching Button

Schneider

9

Inching Button

Schneider

10

Inching Button

Schneider

11

Scram Button

Schneider

12

Power Supply Switch

MW

13

Radiator fan& Square shield (gray)

China

14

Servo Motor

MITSUBISHI

15

Servo Motor Drive

MITSUBISHI

16

Cylinder

Air TAC

17

Ultrasonic

China

18

Solenoid Valve

Mindman

19

Proximity Switch

OMORN

20

Photoelectric Switch

OMORN

21

Single Phase Motor

SONGGANG

22

Air Switch

Schneider

Serial No

Product name

Product picture

Machine advantage description

1

Servo motor

We use Mitsubishi servo motor to make the machine work stably. Use Mitsubishi servo motor to stabilize the machine It's No.1 brand in the mask machine industry

2

Touch panel

Siemens PLC system

3

Electric control box

We use Siemens PLC system

4

Fan

We installed the fan near the ultrasonic horn to reduce the temperature of the horn and prolong the service life of the ultrasonic. Install the fan near the ultrasonic horn to reduce the temperature of the horn and extend the ultrasonic life

5

Acoustic welding system

Two ultrasonic systems in the ear loop welding machine

6

Finished mask pusher device

Use cylinder type mask finished product pushing device

7

Independent conveyor belt

We install mask sheet conveyor belt

Related Products